Towards zero-error warehousing through autonomous drones

Autonomous drones are transforming inventory management at DSV, and improving safety, boosting accuracy, and delivering cost efficiencies.

Judith Bezuidenhout, national inventory manager at DSV South Africa and Mariano Perna, client success manager at Verity, demonstrated to delegates at the 45th SAPICS Conference just how drones were changing inventory management at DSV.

The project with autonomous drone supplier, Verity, in South Africa complements other DSV projects across the globe. Drones deliver spare parts to offshore wind farms in Denmark (where CO2 emissions are slashed from 6,500kg for a crew transfer vessel to 14kg using a drone) and urgent medical supplies to hospitals in Canada.

Existing inventory management systems were no longer fit-for-purpose and innovative solutions needed to be found. Manual inventory management was labour intensive and prone to errors which spread through warehouses without being noticed. With a turn-over of 8 times a year and two wall-to-wall inventories per year, just roughly 25% of pallets flowing through warehouses were being checked.

Bezuidenhout and Perna said Verity's autonomous drones enabled warehouse employees to be more effective and improved investigation turn-around times - this has decreased from 140 hours requiring 3 people in October and November 2022 to 18 hours in April and May 2023, requiring only one person, created a financial competitive edge through digital transformation and cost savings, and boosted operational excellence through full inventory accuracy.

The combination of autonomous drones, warehouse status reports, improved client culture and processes to work optimally with the Verity system were key milestones in the zero-error warehouse journey.

The impact of automated inventory is easily measurable in certain aspects, but less so in others.

Tangible, measurable impacts include automated inventory tasks, automated lost pallet finding, reduced labour costs and reduced write-offs.

Other, more intangible impacts included increased accuracy in forecasting and replenishment, improved brand reputation, root cause analyses and process improvements, higher data accuracy and higher frequency, release of valuable resources, fewer worker injuries and other labour issues, reduced CO2 emissions, increase forklift driver productivity, increased stock alignment, reduced order delays and less lost sales - and most importantly, happier customers.

There are six easy steps to inventory management using Verity's autonomous drones:

- Inventory tasks are identified by the user or Warehouse Management System (WMS)

- System plans missions that drones execute autonomously, collecting data

- Drones dock to charging stations to download data

- System analyses collecting imagery and 3D data

- System extracts insights using machine learning for actionable reports

- End users act on results reported in cloud-based dashboard

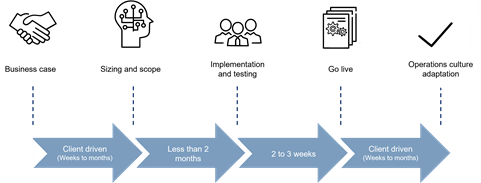

The installation journey consists of four phases:

DSV and Verity have introduced autonomous drone inventory management to DSV Park | Gauteng, with positive results.

Root cause and trend analysis

Root cause and trend analysis

The infographic above measures the instances and occurrences of misplaced stock. It highlights problems that needed to be fixed, and the detailed report enabled resolution of all recorded issues within 24 hours.

The report also allocates all occurrences into “buckets” so we could “close the gap” on instances of misplaced stock.

Click the link below to learn more about DSV's autonomous warehouse management innovation.

Any questions?

Our experts are ready to help. Get in touch and we'll find the solution you need.